0

0General description

TDL-5C Table Low Speed Centrifuge is made of brushless motor and LCD control, centrifugal machine features in stable operation, low noise, delicate appearance, safety-regulative balance and high precision control, TDL-5C Table Low Speed Centrifuge widely applicable for blood and plasma qualitative analysis in hospitals and biological laboratories, medical research and material units.

The machine operates in environment with an ambient temperature 5~40℃ and relative humidity no more than 85%, in which is free of conductive dust, explosive gas and corrosive gas.

Working principle

Put tubes with sample that can be balance into a angle rotor symmetrically, the rotor will spin on axis after you start the machine, and the relative centrifuge force (RCF) comes into being while rotating, It will make the composition at different weight density separate from solution.

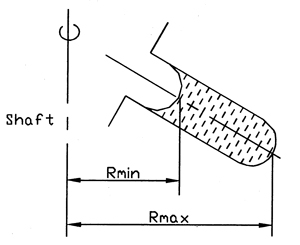

The formula of calculating RCF is as follows:

RCF=1.118×10-5 n2 R×g

n-----rotation speed (rotation/min)

R----- rotation radius (cm)

The times Ts needed for separation and sediment of particle in missed liquid is calculated by the following formula:

Ts=27.4×(logcRmax-logcRmin)μ min n2r2 (σ-ρ)

In the formula:

ρ-----mixed liquid density (g/cubic centimeter)

μ-----mixed liquid viscosity (poise)

n-----rotation speed (rotation/min)

r----- radius of particle (cm)

σ-----density of particle (g/cubic centimeter)

Rmax----horizontal distance from bottom of centrifugal test liquid to axes (cm)

Rmin----horizontal distance from face of centrifugal test liquid to axes (cm)

Technical parameter

Max. rotation speed | 5000 r/min | Timing range | 0~99min |

Relative Max. centrifugal force | 2810xg | Capacity | 100mlх4 50mlх8 15mlх32 |

Input power | 550W | Power | 220V 50Hz |

Fuse specification | 5A | Weight | 45Kg |

Structure

The machine is made of frame, driving system, rotor, and electric control system, damping suspension system and brushless motor.

Operation procedure

1. Before operation, make sure the rotors are properly installed.

2. Put the centrifuge tubes filled with samples with same amount into the rotor in a balanced way.

3. Close the cover, and lock it. Then switch on.

4. LCD display with touch-key screen, press the keys to choose RPM, RCF, Time and rotor number, After setting complete, press "Start" run. Then press“open”when the machine stopped compeltely.

5. Usually when you choose different rotor number (which is on the higher left corner), the speed will and RCF will be automatically shown in the window.

6. Press "Stop" key to stop the machine and the door opens automatically after the rotor stops.

7. Operation ended, switch off power.

Install requirements

The machine should be placed on flat operation table, which is 50 cm away from the wall. The environment condition is clean, dry, and free of conductive dust, explosives and corrosives.

Notes and maintenance

1. Read he instruction sheet before use to avoid mis operation.

2. Install the machine on the fixed and flat workbench to ensure its stable operation.

3. Regularly check the rotor and centrifugal pipe and see if there are crack and aging problems during the using the period of machine. Replace them in time.

4. After the tube is filled with sample, it is put into the rotors. Pay attention to the weight and proportion, make sure load operation and balanced operation and avoid vibration or accident even.

5. Make sure the power supply and cord is correct and the machine is electrically well grounded.

6. When the machine is under working status or it did not stop completely, the cover cannot be open avoid accident.

7. When powered off, make sure the rotor stops totally, and Manual open the cover.

8. Lubricate the motor shaft once in a while.

9. Check the rotor and centrifuge tubes before use, making sure it's not corroded or cracked. Install the rotors by rotor handle.

10. Don't open the cover during running.

11. Don't touch the rotor which is running.

12. Don't run the machine without any rotors.

13. Don't use any damaged or defective rotors.

14. Install the rotor properly and store the rotors in places free of corrosives after use.

15. Clean the machine and its chamber after use.

16 When the machine is not used, cut off the power and pull out the plug to power of outside electric wire network.

Warranties

The warranty period machine is a year. If the machine is damaged by person or disoperation, then our company will charge for repairing.

Usual faults and debugging methods

Number Usual defaults debugging methods Notes

1. Over speed protection 1. check the speed setting

2. Check the speed measuring signs

3. Contact supplier

4. Cover opens when running Close the cover and restart the machine

5. Rotor no wrong Check the rotor and correspond speed No available for this model

6. Program setting error Check all values set for meeting technique requirements

7. No speed Check the power plug-in

8. Unbalance protection Check the samples for equal quantity and proportion No available for this model

Transportation and warehousing

1. The machine shall be stored rain-proof, vibration-proof and moisture-proof packed when out of factory, and shall be fixed in the packing box. The users cannot inverse the position of packing box or throw, impact with heavy force on the box lest the machine should be damaged.

2. If the machine is not used for a long time, it shall be rain-proof, vibration-proof and moisture-proof treat, packed and store in the environment with temperature 5~40℃ and relative humidity no more than 80%,in which is free of corrosive gas and well-ventilated.

CopyRight © 2024 Jiangsu Jinyi Instrument Technology Co.,Ltd All rights reserved Sitemap All tags Designed by Zhonghuan Internet